3D printing and modelling service is revolutionizing the way products are designed and manufactured. With the ability to create intricate and complex designs with ease, this technology is changing the game for industries across the board.

What is 3D Printing & Modelling Service?

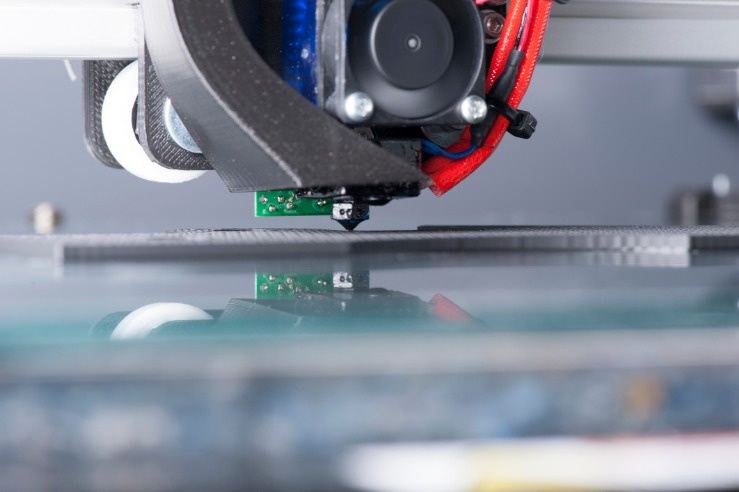

3D printing is a process of creating three-dimensional objects from a digital file. It works by adding material layer by layer until the final object is formed. On the other hand, modelling service involves creating a digital model of the object before it is printed. Combined, these services allow for the creation of highly detailed and accurate physical objects.

Benefits of Using 3D Printing & Modelling Service

- Customization: 3D printing allows for the creation of bespoke designs tailored to individual needs.

- Efficiency: The speed and accuracy of 3D printing can significantly reduce production time and costs.

- Complexity: Intricate designs that were previously impossible to manufacture can now be created using 3D printing.

- Prototyping: Rapid prototyping allows for quick iterations and adjustments to designs before final production.

Frequently Asked Questions

Is 3D printing suitable for mass production?

Get more information about 3d printed products here.

While 3D printing is great for creating prototypes and small batches, it may not yet be cost-effective for mass production due to limitations in speed and volume.

What materials can be used in 3D printing?

A wide range of materials can be used in 3D printing, including plastics, metals, ceramics, and even food and biological materials.

How accurate are 3D printed objects?

3D printing can achieve high levels of accuracy, with some printers capable of producing objects with precision down to a fraction of a millimeter.

Overall, 3D printing and modelling service is transforming the way products are designed, prototyped, and manufactured. With its myriad benefits and endless possibilities, this technology is sure to shape the future of manufacturing in exciting ways.